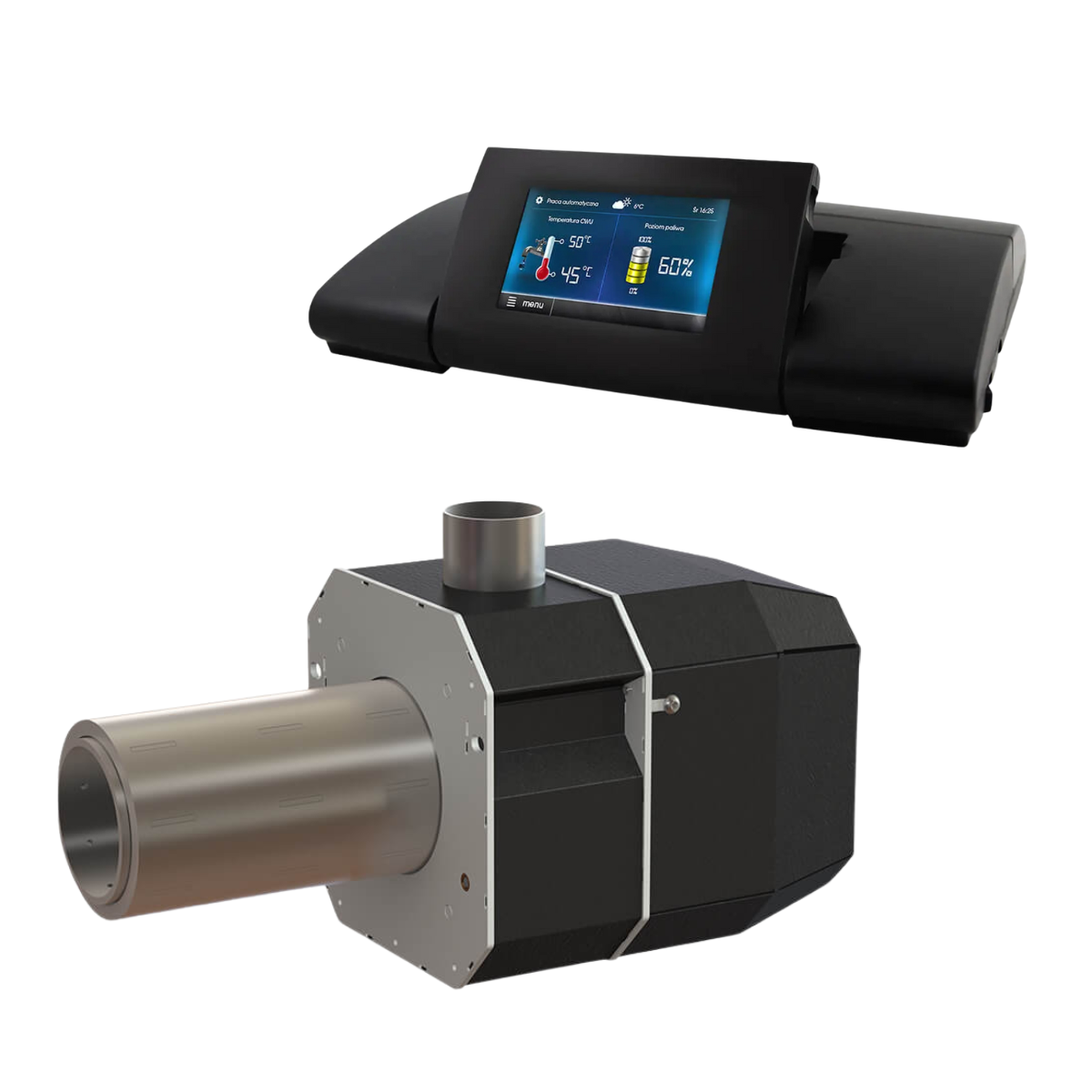

The KIPI pellet burner operates automatically and does not require supervision. The rotating combustion tube prevents slag and other combustion residues from accumulating inside the burner during operation. While operating, the combustion tube rotates cyclically, causing ash and slag to be expelled from the combustion area.

The pellet burner is designed for installation on solid fuel boilers, pellet boilers, as well as various gas and oil boilers, provided the combustion chamber is large enough for the ash to accumulate at the bottom.

The pellet burner is environmentally friendly, as it uses renewable energy sources as fuel. It also has a low electricity consumption.

The burner is equipped with a control unit that ensures optimal operation according to the mode and parameters set by the user. The automation can be connected to a room temperature sensor and an outdoor temperature sensor. The standard package includes sensors for the boiler and domestic hot water. The control unit can also manage heating and hot water pumps as well as the boiler's mixing valve.

The burner includes safety automation that blocks fuel supply in case of overheating or flame control failure. In the event of a power outage, fuel feed stops automatically to prevent damage to the burner and other equipment.

Only pellets with a diameter of 6–8 mm and a length of 3.15–40 mm may be used as fuel.

With the purchase of an additional device, it is possible to monitor and configure the burner remotely over the internet (provided the customer has an internet connection).